Smart Outsourced Tea Cultivation Service Management Creates Value-added Services through Data Analysis

Since its inception in 2007 by the Council of Agriculture (COA), Executive Yuan, the AGTECH Program has subsidized 100 projects, and for each NT Dollar that the government spent in subsidy would in turn result in an average of NTD 1.49 direct investment from the industry and yield NTD 6.12 worth of production value. Moreover, the derivative investment that comes from the enterprises is over NTD 1.8 billion. The COA commissioned Taiwan Institute of Economic Research (TIER) to organize the AGTECH Program R&D Results Exhibition and Exchange event, which is held on Nov.13th at the Chang Shen Tea Factory where the company Siang Shin showcases the results of its project named the Development of Smart Outsourced Tea Cultivation Service Management System, including labor dispatch operation and farming machinery operation data tracking. Compared to traditional manual recording of outsourced cultivation operation, the said system utilizes IoT equipment and records outsourced cultivation process as well as tea harvest data in cloud. The method helps outsource service providers in the planning and scheduling of labor dispatch, which increases management efficiency significantly.

From tradition to technology: integrating software and hardware to better assist outsourced tea cultivation service

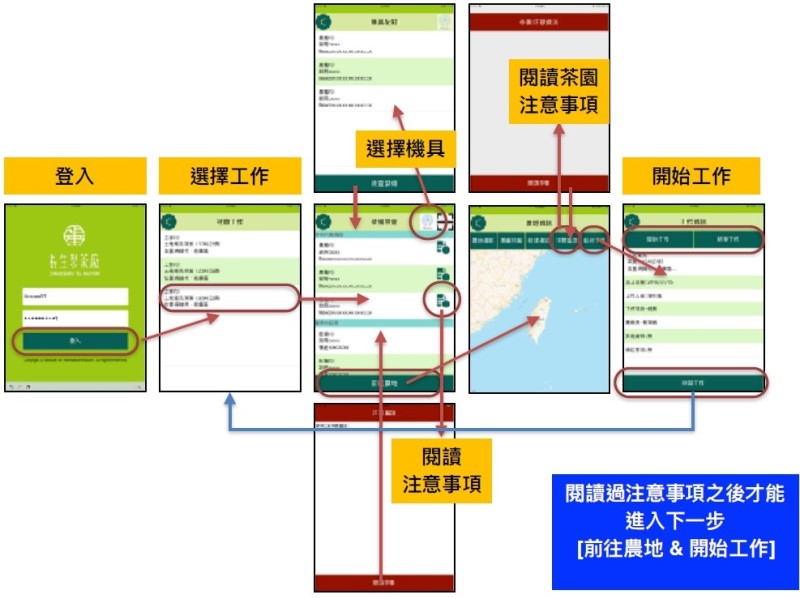

The COA pointed out that the said project mainly focuses on utilizing agricultural machinery combined with sensors to perform automatic gathering and recording of data for traditional tea plantation operations such as tea plucking and pruning. The objective is to collect data related to outsourced cultivation like field, weather, labor, farm machinery, tasks, materials, and footages, which will help service providers to optimize dispatch schedule in order to elevate machinery availability by understanding the cost of each operation. Furthermore, by integrating data interpretation and practical tea industry experience, real-time guidance on tea plantation management can be provided to owners, which strengthen cooperation between tea farmers and further establish brand value.

The COA explained that according to Siang Shin’s preliminary estimate, the combination of Riding-type Tea Plucking Machines with management system can save more than 25% in labor and fuel cost as compared to traditional one-man or two-men operated tea plucking machines. It is also possible to save up to 75% more time than usual procedure for each operation, thus reducing tea plantation front-line personnel preparation time. Moreover, GPS track records can serve as references for subsequent field operations. In addition, automatically registered machinery mileage records can serve as benchmarks for future maintenances, therefore upholding each dispatch operation’s quality and optimal farm equipment running efficiency.

The COA indicated that Siang Shin has developed a system that provides clients with value-added services such as pesticide safety, production yield, or harvest period prediction based on many years of practical tea plantation management experience, along with data gathered via tea cultivation service. The company will continue to promote the said system in Hsinchu, Nantou, Hualien, and Taitung after the project finalizes. It also plans to expand the number of its clientele and the area of service by around 9.7 hectares annually; therefore, gradually provide relief to the problem of labor shortage that tea plantations are facing while ushering the traditional outsourced tea cultivation service into the intelligent age.