Moving towards Agricultural 4.0 in Taiwan with Smart Technology

2016.7 (Issue No. 289)

I. Introduction

Total global population is expected to reach 7.5 to 10.5 billion by 2050, which will intensify the pressures of food demands. As a net food-importing country, Taiwan's calorie-based food self-sufficiency rate is relatively low. At the same time, with global warming causing more and more extreme weather changes, it is inevitable that there will be shortages in food supplies and escalations in food prices.

Additionally, rapid aging and decreasing birth rates in rural communities are leading to dramatic shortages in manpower and impacting on agricultural productivity. Due to restrictions from the natural environment and high production costs, Taiwan’s agricultural industry is less competitive compared with other countries in the world. In order to boost agricultural productivity, it is necessary to adjust industrial structures to make room for technological innovation.

II. Agricultural 4.0 Scenarios in Taiwan

An unmanned aircraft can fly over fields to monitor crop growth and transmit data to the cloud for analysis of the use of pesticides and fertilizer as well as water resources; results of the analysis could lower costs and minimize environmental impact. All that farmers need to do is connect to the cloud using a cell phone or tablet.

Using big data analysis, farmers can get a better grasp on their crops, microelements and nutrients in the soil, irrigation schedules, crop rotation, and other conditions affecting crop growth. Vane sensors can measure the pressures of plant moisture while soil sensors can track water movement, soil moisture levels, and carbon and temperature changes, all of which can be used to optimize irrigation and decrease crop damage. Pictures of crops can be uploaded to a database to serve as a reference for daily pricing updates. Thus, farmers no longer need to leave their farms to participate in global economic activities.

From the comfort of their homes, consumers can scan QR codes on packages to view the clean automated control processes of king oyster mushroom production and harvest procedures taking place in plant factories. Overseas retailers can remotely access supply chain systems and rapidly distribute Taiwan's exported agricultural products to international retail stores. Fresh mushrooms ordered 7 months in advance can be prepared for export through a RFID system.

All the above are possible future scenarios of Agricultural 4.0.

III. Smart Agriculture 4.0 Program

The Council of Agriculture (COA) is currently promoting Smart Production and Digital Services in the agricultural industry to optimize manpower, resources, and the overall industry.

Agricultural production, marketing, and consumer markets can be structured using strategies such as "promotion of development and application of smart agricultural production technology via smart agriculture alliances", "building agricultural productivity knowledge and service support systems to integrate information and communication technology for convenient service and value chain application of diversified digital agriculture", and "creating new communication models between producers and consumers through user-friendly interactive technologies" (Figures 1 and 2).

Through sensors, smart devices, Internet of Things (IoT), and big data analysis, knowledge can be digitalized, production can be automated, products can be optimized, operations can be simplified, and products can be traced through computerized systems for the purposes of intelligent production and digital marketing.

Intelligent production technologies and smart management applications could help small farmers overcome challenges and increase overall production efficiency and quantity. Big data techniques could help to establish a comprehensive consumption service platform through analysis of supply and demand data, thus, on the one hand enhancing agricultural product safety and consumer loyalty, and on the other hand, creating international brand visibility for Taiwan’s unique smart agriculture technologies and services through strategic marketing and business counseling on product internationalization. Whole-factory exportation of leading agri-technologies could help to introduce outstanding agricultural products to the rest of the world.

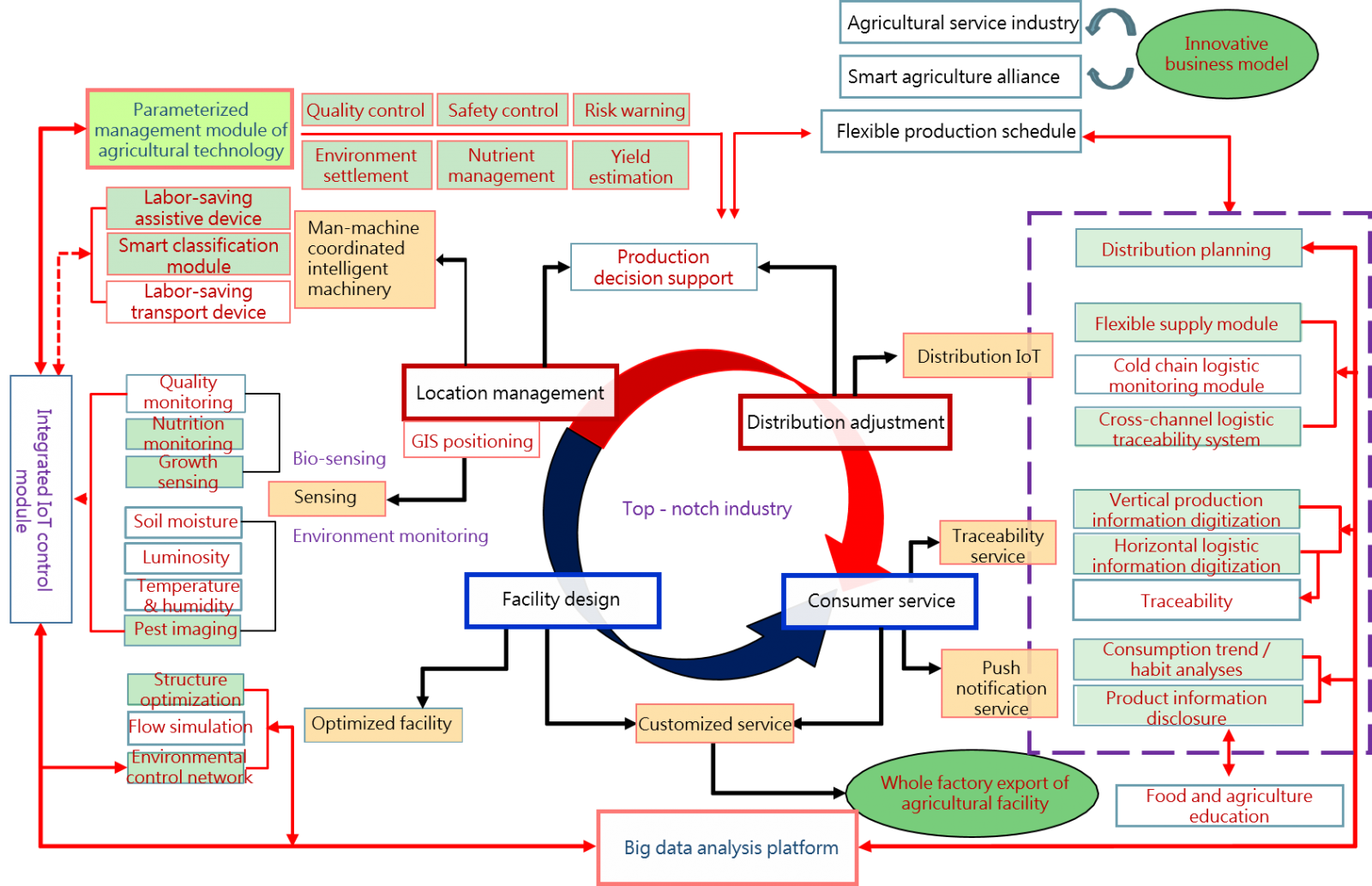

Figure 1: Diagram of "promotion of development and application of smart agricultural production technology via smart agriculture alliances" strategy.

Figure 2: Diagram of "building agricultural productivity knowledge and service support systems to integrate information and communication technology for convenient service and value chain application of diversified digital agriculture", and "creating new communication models between producers and consumers through user-friendly interactive technologies" strategies.

IV. Smart Agriculture 4.0 scope and application objective

In order to promote the Smart Agriculture 4.0 Program, the COA targeted three major fields, namely agri-biotechnology, quality agriculture, and precision agriculture; precision agriculture is divided into two major categories: establishing foundations and promoting excellence. Ten leading industries, including moth orchid, seedling, mushroom, rice, agricultural facility, aquaculture, water fowl, traceable agricultural product, dairy, and marine fishery industries were prioritized for promotion. The current technical status of the aforementioned industries and post-promotion applications of the Smart Agriculture 4.0 Program are shown in Figures 3 to 7. Specific industrial and cross-industrial promotional contents and objectives are as follows:

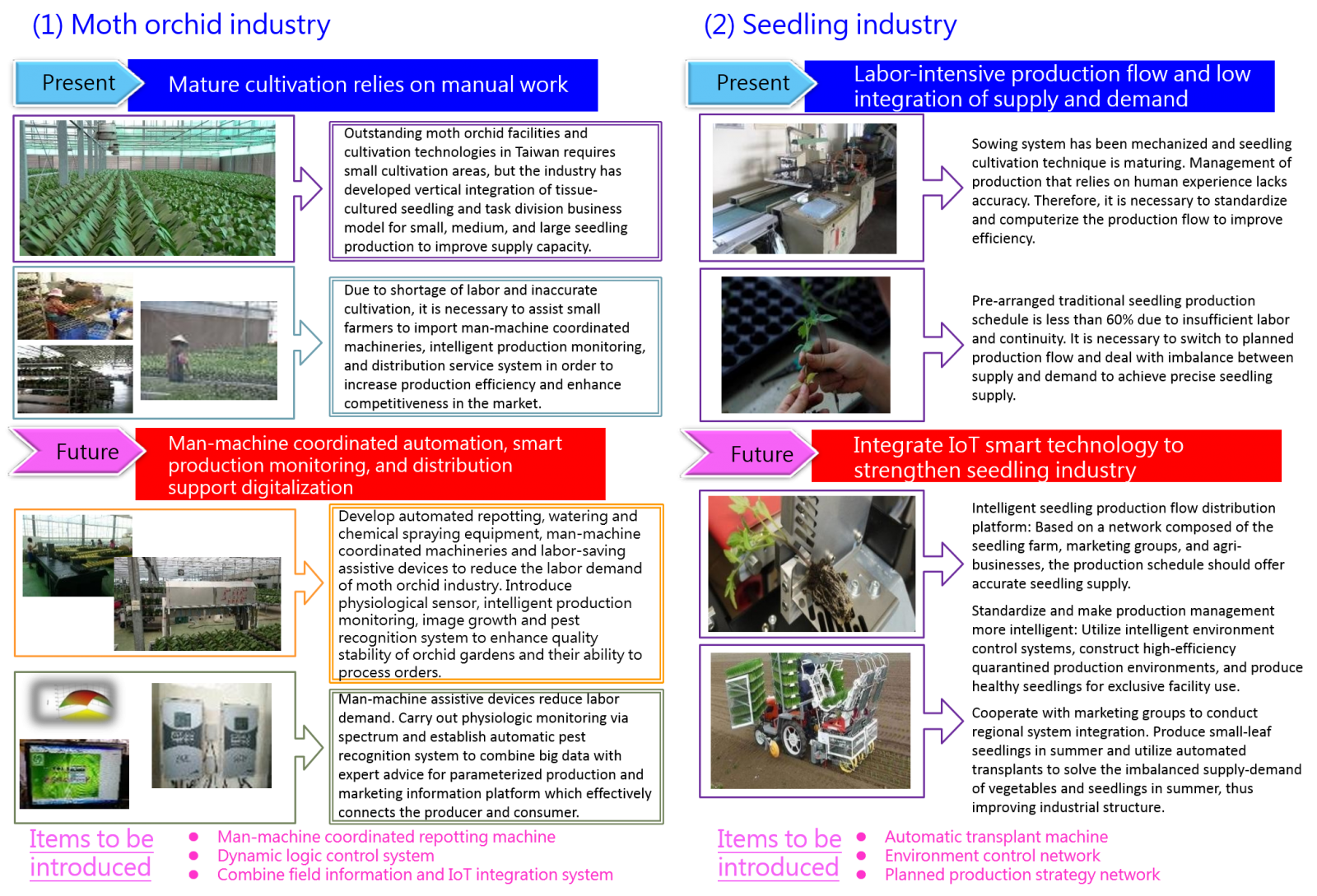

(1) Moth orchid industry

The focus here is on developing automatic repotting techniques, watering and chemical spraying equipment, and production models to reduce the labor demand for moth orchid industry, as well as introducing physiological sensors, intelligent production monitoring, image growth and pest recognition systems, and alternative mediums to elevate quality stability and order processing of orchid gardens.

Furthermore, the government hopes to establish smart logistic management systems of plant tissue culture, and utilize tissue cultivation intelligent production and marketing services to develop new models, smart production process management, and an IoT logistic service which integrates physical factories (production) and virtual stores (marketing), thus connecting tissue-cultured seedlings to digital seedling production management systems. Establishment of relay production and technical diagnosis expert systems could aid the industry in regaining former European markets and even move towards new emerging markets such as Brazil.

(2) Seedling industry

Applications include using seedling supply systems such as seedling farms, production and marketing groups, and agri-businesses as examples to develop cultivation schedule networks and seedling production intelligent business management models in order to raise the accuracy of seedling supply.

Establishing seedling operation parameters for smart networks based on a common big data platform could reduce labor consumption and raise seedling management accuracy and quality. Automation efficiency of plug seedling transplant machines could be improved through upgrades of the mechanism. Furthermore, the efficiency of bulk vegetables automatic transplant machines and the R&D of intelligent machineries such as labor-saving transplant machines for green-leaf vegetable could be enhanced.

Figure 3: Current technological applications of moth orchid and seedling industries, and application objectives after implementing Smart Agriculture 4.0.

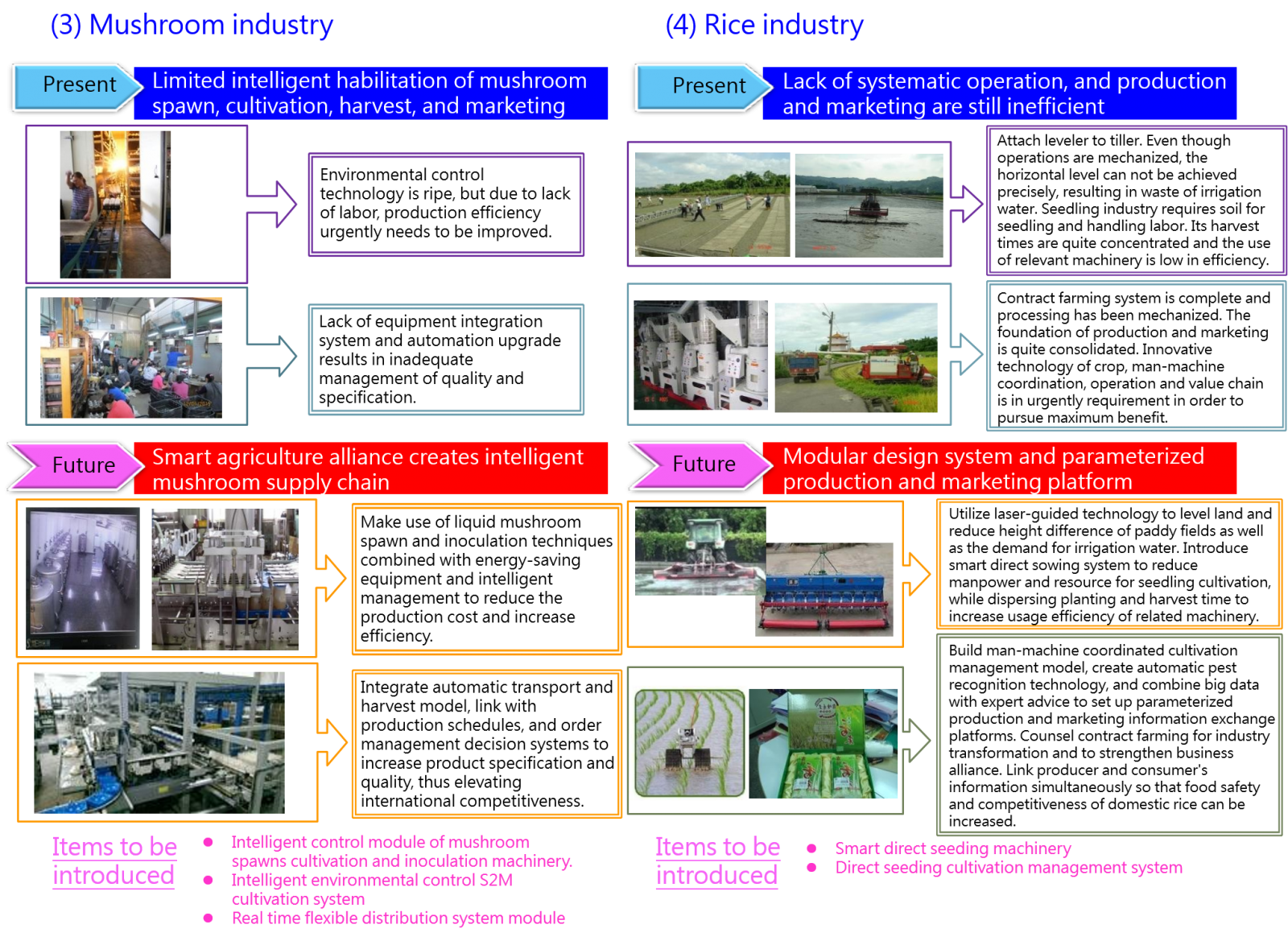

(3) Mushroom industry

Smart Agriculture 4.0 aims to develop full environmental control, harvest automation, and smart production of mushrooms for future industry regeneration. Through research related to the development of mushroom production and relevant machinery software and hardware, as well as the integration of energy-saving equipment, the Council hopes to coordinate demands from producers, suppliers, and consumers in order to elevate the overall competitiveness of Taiwan’s mushroom industry.

(4) Rice industry

The focus here is on developing rice intelligent broadcasting systems and man-machine coordinated smart rice cultivation management systems through strategic alliance. Through labor- and effort-saving intelligent rice production and management, a new form of agricultural service industry could be generated to enhance production efficiency and industry competitiveness by linking information of producers and consumers. Active comprehensive rice consumption and service platforms could be established through big data analyses, and could help to strengthen consumer perceptions of domestic rice safety.

Figure 4: Current technological applications of mushroom and rice industries, and application objectives after implementing Smart Agriculture 4.0.

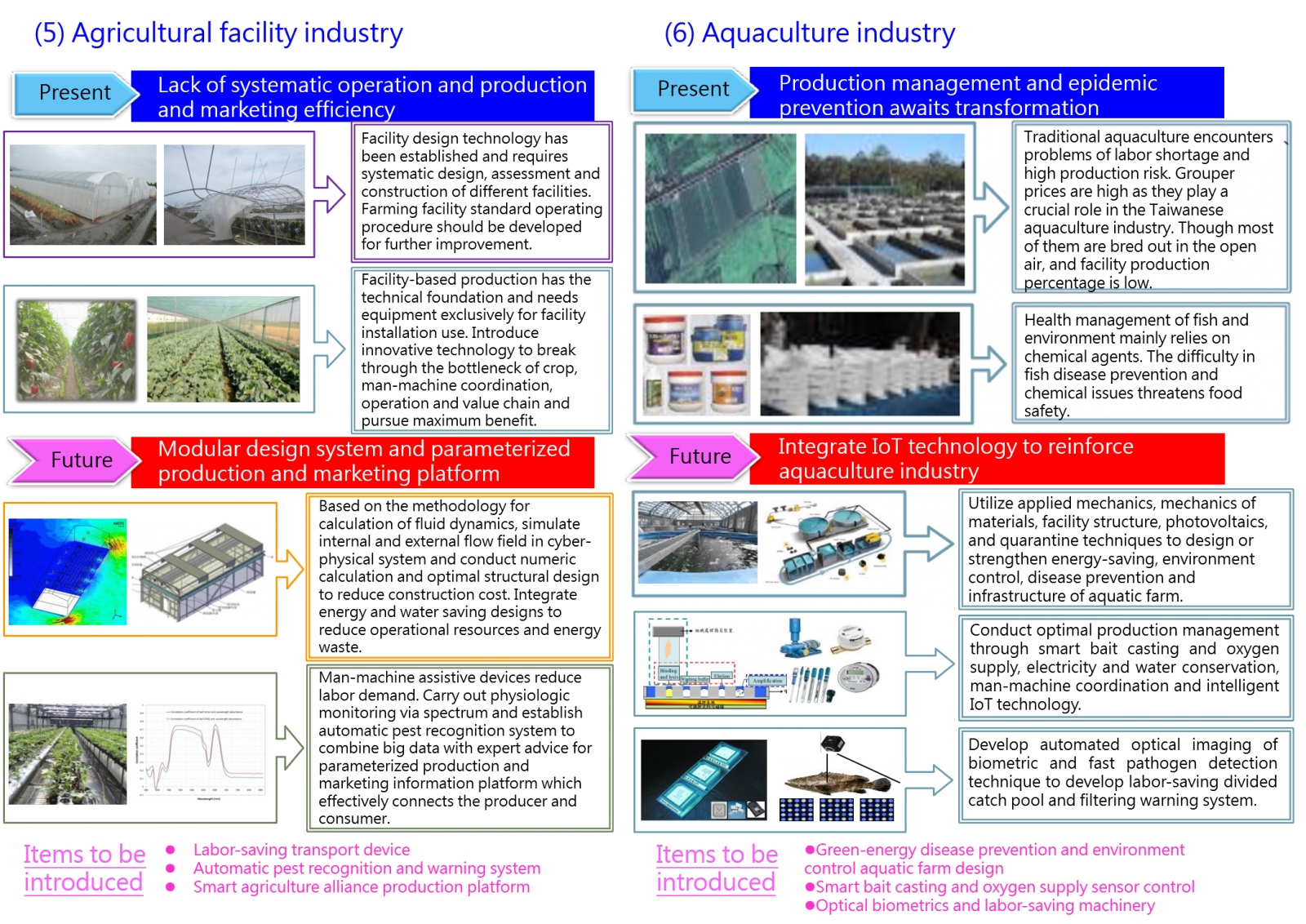

(5) Agricultural facility industry

Adoption of Smart Agriculture 4.0’s crucial technologies from production manufacturing to sales service including design planning, control models, and management systems; development of modular design systems, IoT environmental control modules, labor-saving transporters and assistive equipment, and parameterized intelligent production and marketing management information exchange platforms facilitating inter-disciplinary cooperation. Upgrades of greenhouses could reduce manpower by more than half and efficiently control cultivation environments. All of the above changes could raise product quality and form a standardized and highly efficient agricultural facility. The COA hopes to improve Taiwan’s agricultural facility design and integrated technology, to achieve industrialization and pave the way for whole-factory exportation of agricultural facilities.

(6) Aquaculture industry

Utilization of IoT techniques that integrate with big data analyses and link to production and marketing demands of major enterprises could help with the development of advanced automated control support systems such as smart environmental sensors for aquaculture, fish disease prediction support systems, smart energy-saving cultivation systems, and others; construction of intelligent modular breeding/cultivation facilities with epidemic-prevention and quarantine capabilities for the cultivation of high-quality products can aid the aquaculture industry in moving towards automated production, intelligent management, and technological development as production efficiency is elevated. Projected water conservation, labor saving, and capacity adjustments can also be achieved. Eventually, all of the aforementioned integrations can be sold to private enterprises as a whole-factory package, making intelligent aquaculture the dominant form of industrial management for the future.

Figure 5: Current technological applications of agricultural facility and aquaculture industries, and application objectives after implementing Smart Agriculture 4.0.

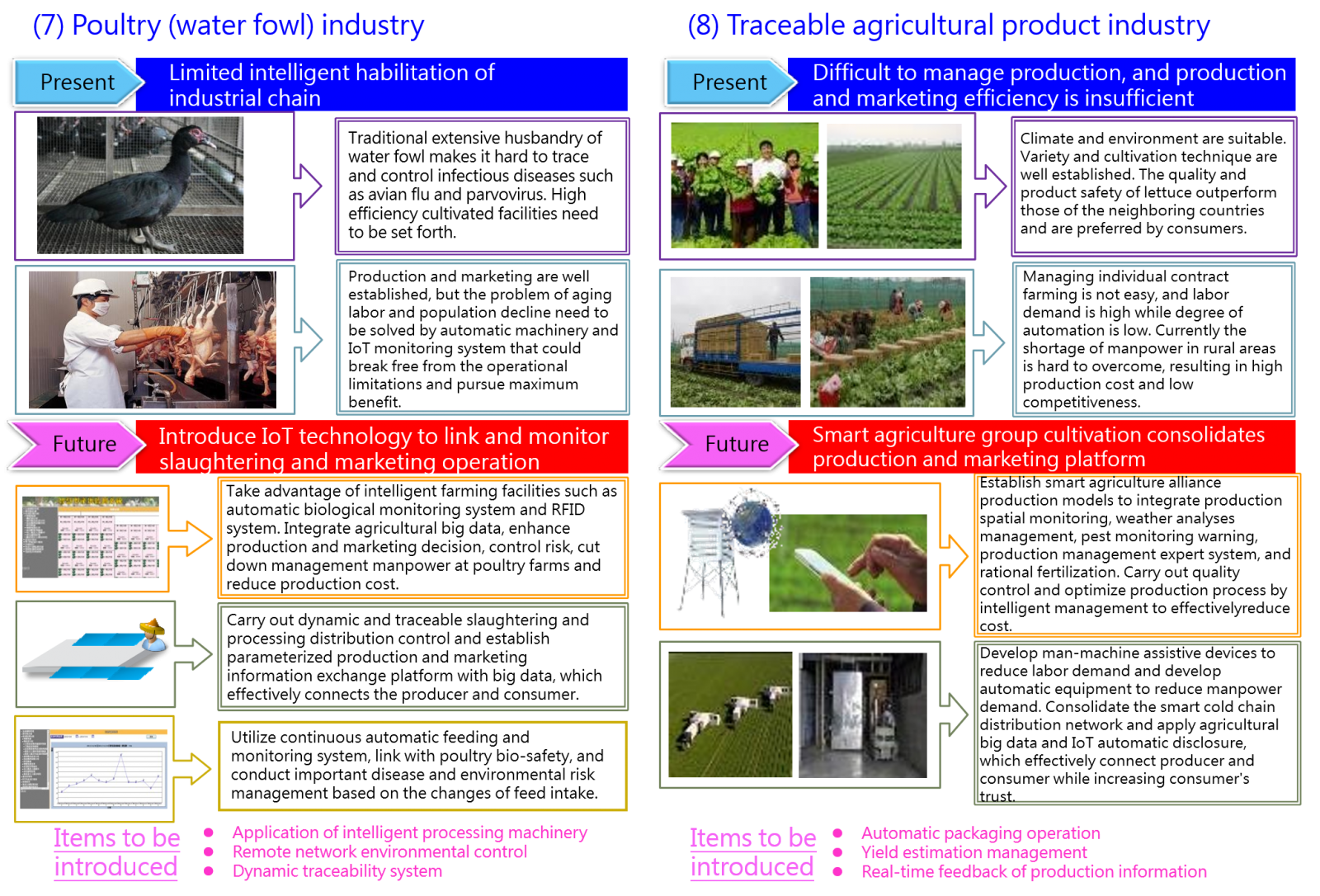

(7) Poultry (water fowl) industry

Developing smart IoT contract farming management systems and setting up certification platforms to form production processes in line with international food safety standards while monitoring quality standards from farm sources to sales, thus elevating export benefits. Peripheral technology and consulting services for smart IoT management systems could also potentially be exported. We use the poultry and egg model as an example, but this system could be expanded to other livestock industries such as the pig or cattle industries.

(8) Traceable agricultural product industry

Initially, cloud medium mechanisms and traceable agricultural product systems such as the organic traceability system, good agricultural practice (GAP), and autonomous traceability management systems were established with the goals of enhancing traceability and enhancing consumer trust for domestic agricultural products. Featured items include eggs, aquatic products (white shrimp, clam, oyster, grouper, milkfish, tilapia, and bass), agricultural products (mushroom, bee products, and coffee), and traceable agricultural product information exchange and disclosure platforms (organic, TAP, GAP, autonomous traceability management, etc.). Crucial R&D items include the TAP system, traceability information exchange platforms, interfaces for big data collection and application, TAP supply chain, and measures for improving TAP quality.

Figure 6: Current technological applications of Poultry (water fowl) and traceable agricultural product industries, and application objectives after implementing Smart Agriculture 4.0.

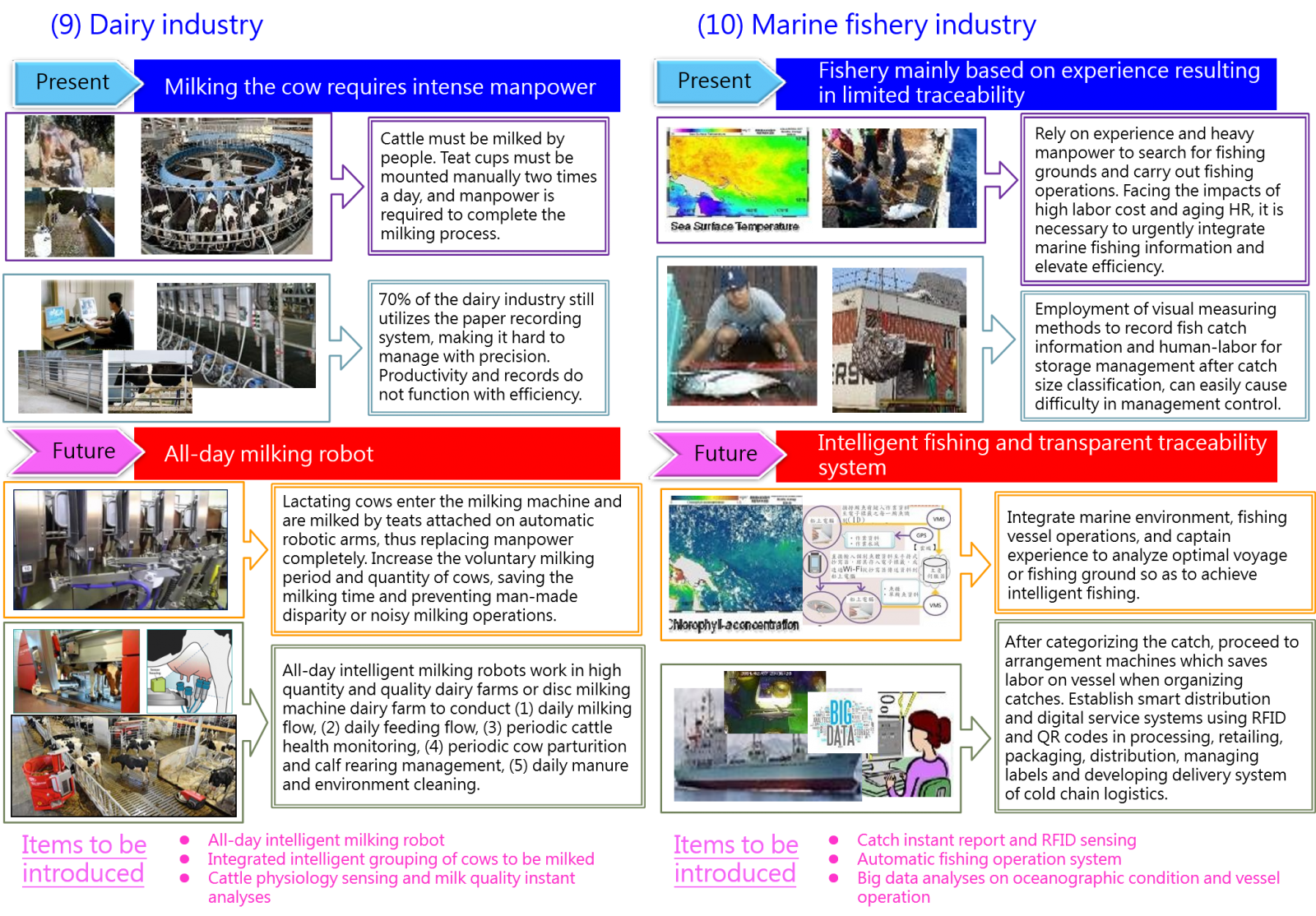

(9) Dairy industry

Utilization of smart milking robots at existing high quantity and quality dairy farms or disc milking machine dairy farms to assist dairy farms in the implementation of routine work including daily milking, daily feeding, periodic health monitoring, periodic cow parturition and calf rearing management, and daily manure and environment cleaning. These intelligent robots could decrease manpower requirements and form a new system of dairy business with unmanned milking and farming management systems, promoting the development of 24-hour milking robot components and system integration.

(10) Marine fishery industry

Utilization of Smart Agriculture 4.0 crucial technologies to establish fishing condition production service support systems, as well as develop energy and labor saving machinery and TAP monitoring systems that integrate interdisciplinary electrical engineering technology. Hopefully, smart monitoring and sensing can raise transparency of fish distributions, which can be helpful in offering consumers more gastronomic choices. Moreover, big data analyses can help track distribution of fish catches, enabling proper adjustment of inventory and export volume, thus avoiding production and marketing imbalance and maintaining industrial competitiveness.

Figure 7: Current technological application of dairy and marine fishery industries, and application objectives after implementing Smart Agriculture 4.0

(11) Interdisciplinary crucial technology application framework

In order for these technological developments and applications to be implemented for industry use in the above 10 leading industries, intelligent production and digital service industry application frameworks based on interdisciplinary technology would need to be constructed.

For example, in the agricultural facility industry (Figure 8), technologies facility design, location management, distribution adjustment, and consumer service form the pillars for sensors, monitoring, decision-making, and automatic feedback. With the support of common big data analyses platform, big data could be accumulated from environment sensors and crop physiological sensors.

Through integrated of IoT control models, coordinated machinery could be utilized for information collection. Following calculation and comparison of agricultural technical parameter management, the system could then proceed with crop quality control, pest prevention, external risk warning, facility environmental harmony, cultivation nutrient management, and production yield and lead time forecast. Moreover, the system could further conduct marketing planning, flexible supply prediction, cold chain logistics, and inter-retailing traceability processes.

The consumer service pillar can be further divided into traceability services and notification services. Traceability services digitalize vertical production information and horizontal distribution information to form a complete traceability system. Notification services can disclose all the information (production, distribution, nutrient components) of an agricultural product through user-friendly interfaces and also return feedback on consumers’ purchasing habits and analyses trends for producers, enabling mutual interaction. The data collection and analytical applications of big data can link production management with marketing and balance production and marketing using flexible production schedules. A novel smart agriculture alliance can generate knowledge-based agricultural services that offer agribusiness risk analyses and integrated cultivation management and consultation services based on an intelligent production and digital industrial application framework.

Figure 8: Interdisciplinary crucial technology application framework of smart production and digital service industry (using agricultural facility industry as example).

V. Smart Agriculture 4.0 and related support measures

Apart from the technical level, this project could help our agricultural industries rise to international levels. In order to shorten R&D time, the COA continues to enhance foreign research capacities and innovation through cooperation with overseas research institutes. Moreover, the COA also continues to develop export technology and equipment in tandem with domestic and foreign enterprises. Standardized and horizontal alliance platforms and knowledge banks are being developed as the COA strengthens international interdisciplinary industry-academic-research cooperation and whole-factory export capacities.

In terms of talent-fostering, a new agricultural training strategy is being developed for the new generation; this training closely complies with the framework of smart agriculture 4.0 while at the same time targeting the demands of leading industries with regard to on-the-job training and international expertise. In order to speed the import of agriculture 4.0 capacities and technical consultations, experts and scholars from industry-government-academic-research alliances have formed the “4.0 Industry Service Team” for 10 leading industries. There are also 3 professional technical groups, namely the “Intelligent Production and Man-Machine Coordinated Assistive Device Development”, “Agricultural Technical Expert System Implementation”, and “Digital Service and Traceability Data Exchange Application”, as well as 1 technical support group for “Business Management and Operation Support”.

To encourage different perspectives when handling enterprises' utilization of agriculture 4.0, the COA seeks to consolidate the function of all service groups. After interdisciplinary experts from industrial service groups confirmed objectives of each leading industries, attention was focused on the investment of resource projects and technologies, building R&D capacity of planned projects, selecting cooperative enterprises with proper infrastructures, and taking advantage of project resources to offer each demo venue consultation and inspection visits. Through technical counseling and management advice from designated industrial service teams, customized services could be carried out for the leading industries. Demo venues offer consultation, R&D planning, as well as customized service and counseling, all of which is expected to achieve the Smart Agriculture 4.0’s objective of industrial expansion and inject new dynamism in sustainable development of Taiwan’s agriculture.

VI. Conclusion

Implementation of smart agriculture innovative technology frees future agriculture from restrictions set by weather conditions. Crop potential can be greatly enhanced through labor-saving and large-scale production. Safe and convenient agricultural environments could be created to attract young talents, driving Taiwan’s agriculture towards a young, vigorous, and highly competitive LOHAS industry. In addition to offering stable, fresh, and safe food while boosting local consumption, these applications can also help to develop an export industry with international competitive strength.